EPLAN Consulting

Discover the Enormous Potential for Your Company Processes with EPLAN

Our experienced EPLAN consultants will help you to utilise EPLAN solutions efficiently and introduce new engineering methods. In addition, the consultants can work with you to unlock the enormous potential for implementing integrated working processes in your company. To ensure that you get the most value from our solutions, our advice is tailored to your needs and is specific to project phases. Take the next step towards greater efficiency by working with EPLAN consultants. We’re looking forward to supporting you!

More Efficiency in Engineering – Our Mission is to Create More Value for You!

Optimising your engineering processes is the focus of our services. As an experienced partner, we are here for you, providing support and advice through all project phases.

EPLAN is Here for You

Even after trouble-free IT implementation, your staff may sometimes still have questions about the applications or have training needs. EPLAN offers numerous varied service offerings for comprehensive support.

EPLAN Training Academy

The EPLAN Training Academy is your point of contact for all questions about engineering qualifications. Take advantage of our varied training offerings and, for example, train your employees to become EPLAN Certified Engineers (ECE).

Starting in 2020, we will also be offering a qualified certification programme for companies, the EPLAN Certified Company (ECC).

EPLAN Personal Coach

Individuelles Intensivcoaching für EPLAN Anwender: Der EPLAN Personal Coach betreut Ihre Mitarbeiter über vier Tage im Arbeitsalltag und führt sie mit geringem Aufwand direkt zur optimalen EPLAN Umgebung. Zeitraubendes Herumprobieren war gestern − durch das persönliche Coaching können EPLAN Anwender genau das Know-how aufbauen, welches sie für ihre täglichen Engineering-Aufgaben in ihrem Unternehmen benötigen.

Step by Step to More Efficiency

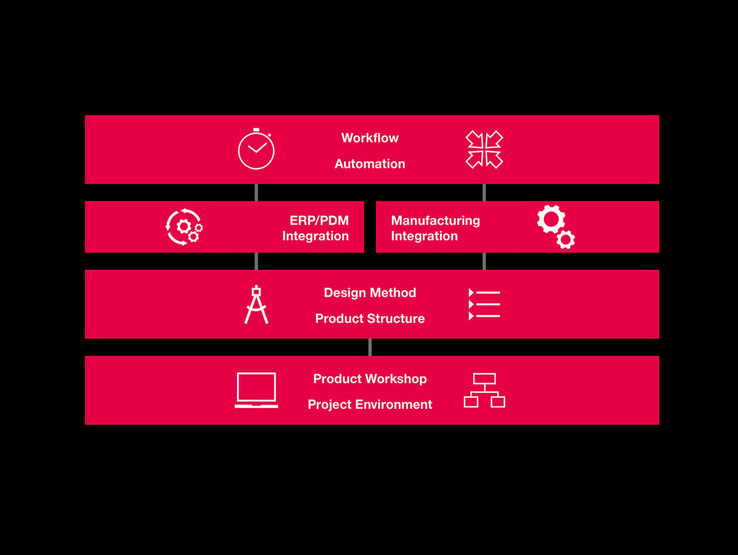

EPLAN Experience is a concept that provides you with specific recommendations for action for process optimisation. It shows you how you can work in a functionally structured way and follow common standards. You can use this solid foundation to increase your engineering efficiency step by step. The focus is on eight fields of action. This can be a specific subject area in your company, or a process that shows the potential for optimised engineering. Everything can be implemented, but it doesn’t have to be. The concept has an open design: your tasks and assignments determine the need for action – regardless of company size, location or industry.

Efficient Engineering, Efficient Control Cabinet Manufacturing

Everyone is talking about Industry 4.0, intelligent networking, flexible production and smart logistics, and even robotics and big data applications. But what about the strategic digitisation of design processes and designing control technology for machines and plants? This is examined in the “Engineering 4.0” study by the European 4.0 Transformation Center (E4TC) at RWTH Aachen University. Furthermore, the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) specifically dealt with the issue of the future of control cabinet manufacturing. EPLAN Consulting bases its consulting concepts on scientifically substantiated models and structures.